Paper coating chemicals

GT OGR106 Grease & Oil Repellent

Description

GT OGR106 is a high performance, water-based cationic fluorochemical agent specifically designed to impart oil and grease resistance to pulp molding products, paper and paperboard without changing the feel or appearance.

This product is based on short-chain molecules that cannot break down to PFOA in the environment. It can be applied internally in the wet end or on the surface of paper or board.

Benefits

GT OGR106 imparts excellent water and oil repellency to pulp molding products, paper and paperboard. It prevents penetration in products such as take out trays, picnic plates, soup bowls and specialty molded applications. it are readily recyclable. It has low foaming nature. In some applications it will provide sufficient water repellency without any additional sizing agent.

Typical Properties

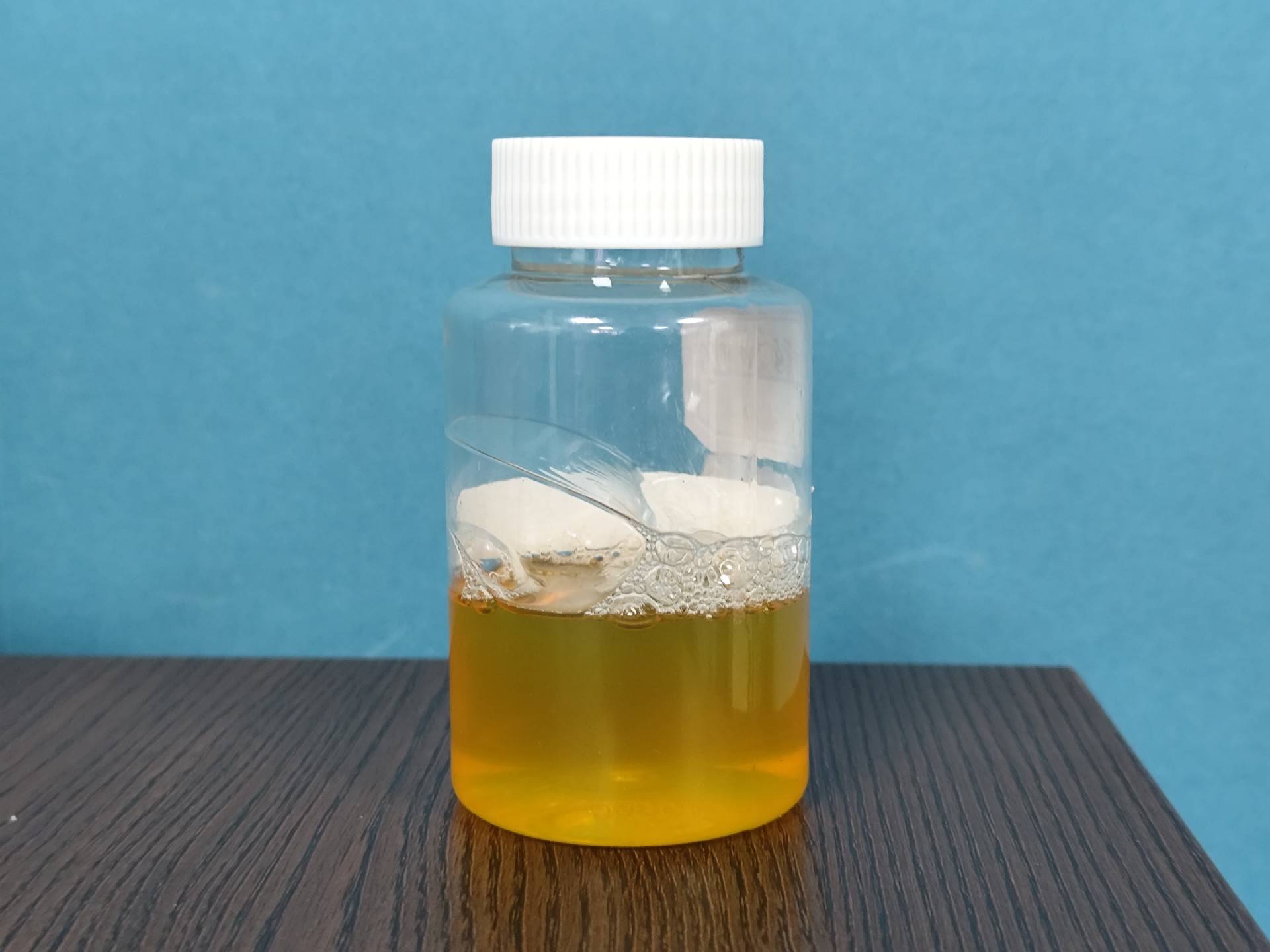

Appearance: amber or light yellow aqueous liquid

pH: 4 - 6

Solids(%) : 20±1

Ionic nature: cationic

Density(@20℃): 1.05-1.1

Product Application

GT OGR106 is intended for wet-end applications with existing thermoforming equipment or surface treatment for providing oil, grease and water repellency to a wide variety of applications.

For molded pulp, the recommended dosage is 0.8–1.2%.

For the surface treatment application, the recommended dosage is 5-20kg/ton paper.

It is cationic product, which have good compatibility with other cationic or non ionic chemicals. Anyway, it is recommended to check its compatibility with the system prior to use. The product can be diluted to any concentration with soft or deionized water. The dilution step should be carried out with good agitation in order to assure proper dispersion. It can be applied in conjunction with sizing agent to produce pulp molding products or paper products. Where additional water repellency is required, It can be applied with hydrocarbon-type water repellents. If the system contains a large number of bubbles or dissolved gases, we recommend to add suitable defoaming agent since air bubbles and dissolved gases can affect the performance of GT OGR106. Lab test is strongly recommended to carry out to determine the best formula and the optimum dosage before the formal using.

Regulation

INTERTEK

---USA FDA 21 CFR 176.170

---CHINA GB9685-2016

---EU RoHS Directive 2011/65/EU Appendix II Amendment Directive (EU) 2015/863

Toxicological Evaluation

---Acute oral toxicity test in rat

Package & Storage

200KG plastic drums /1000KG IBC

Store at temperatures between 0°C and 40°C.Keep tightly closed in a dry, cool and well-ventilated place.

The shelf life is 12 months.

Healthy and Safety

Before using this product, please read the Material Safety Data Sheet and follow all applicable directions.

Important note

All data contained in this technical information are based on actual experience and intended for informational and guidance purposes only.

No liability is accepted per the document.

Copyright © 2022 Great UnionTech Co.,Ltd. All rights reserved. Great UnionTech, GT & any associated logos are registered trademarks or copyrights of Great UnionTech Co.,Ltd.

Lets Get in Touch!

Make connections, work together, and expand infinite possibilities.

Call us

+86 15005366706

Email us

sales@great-uniontech.com